|

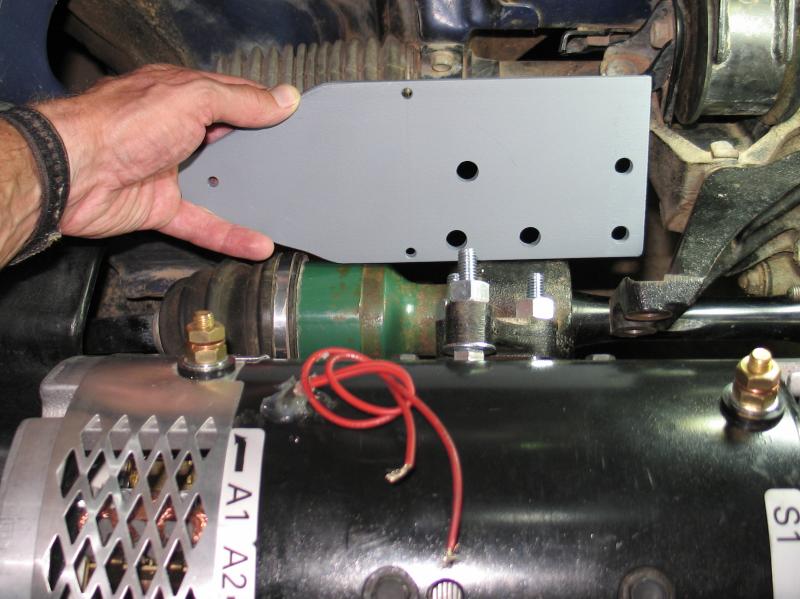

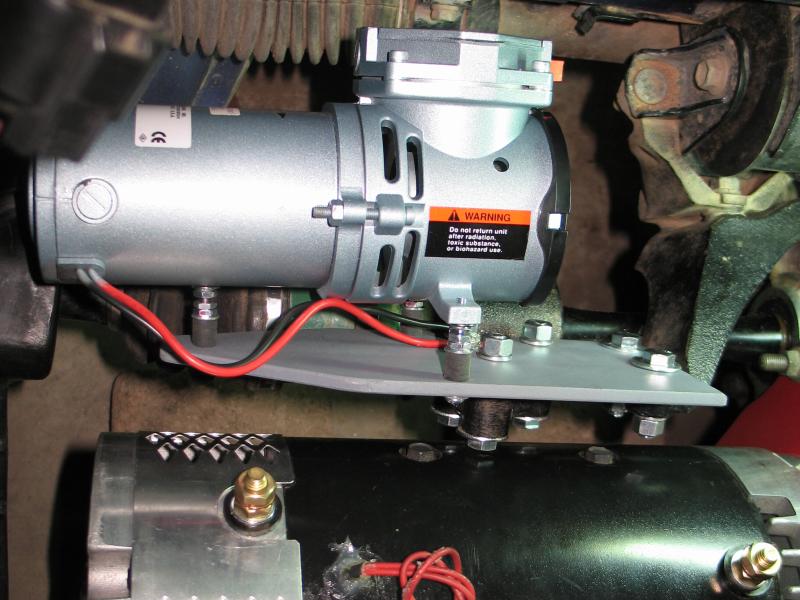

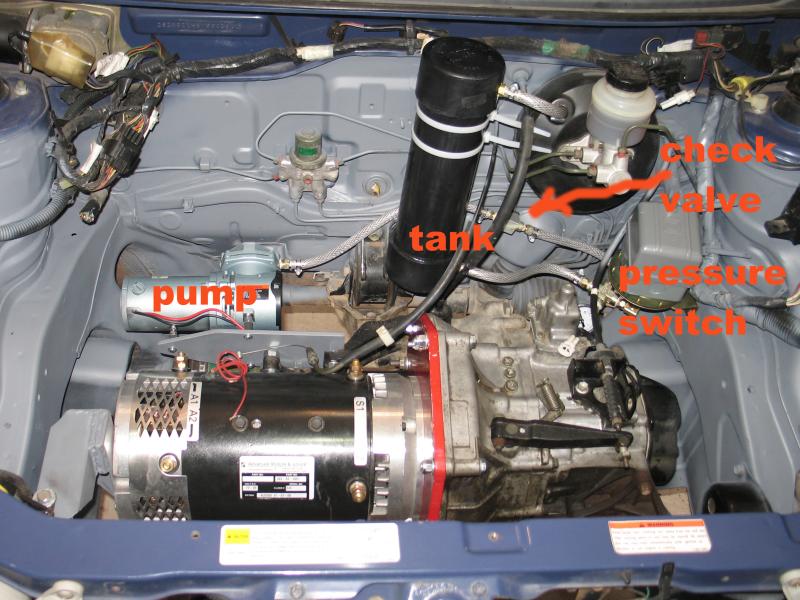

Vacuum Brake System for the Suzuki Swift (Geo Metro/Pontiac Firefly)... Another one of those items that does not come in the kit.... The bracket plate to hold the center axle bearing to the rear transmission mount. It looked like there was room to combine this with a mount for the vacuum pump; which I thought was a great idea since the rubber mounting would further isolate the vibration. For this bracket, I used a piece of 1/4"x4" flat strap and hardware required was (5) 3/16 - 1-1/2" bolts, nuts, lock washers, washers. I also used 3 larger nuts as spacers. It is VERY IMPORTANT that the screw going into the motor body does not go in too far as this will interfere with the motor, and it won't turn! Be sure to screw in just thru the casing, and lock in place with a nut.... After one year...Turned out that mounting the pump at an angle was ... over time the vibration fatigue sheared the bolts and the pump was left hanging by the hoses. Next time I would find a place to mount horizontlly, or perhaps suspended in some pipe strapping. I did retro-fit with some strapping, and will add some pix eventually.

At this point I decided to do a quick paint job on the firewall in one area that had a little rust... and then once I got going I just went ahead and did most of the engine bay. Kind of a slop job with no masking or anything, but it did make it look better and should protect a couple spots that were scratched or had small areas of rust. I probably should have done this before installing the motor! While I was waiting for the paint to dry, I crawled under the dash to see if I could pull out the old heater core. Turns out that is a MAJOR job. It looks like the electric heater will go in the middle of the duct close to the fan so I don't have to pull apart the dash.

One important note to consider when you are setting your vacuum switch operational range is your local maximum elevation.... At SEA LEVEL the Gast will produce a max vacuum of about -23 in-Hg. I found out that value is de-rated about 1 in-Hg per 1000' ft elevation. In my case, at 7500 ft, the pump cannot draw down less than -14 or maybe -15, and takes a long time to get the last bit. I ended up setting mine to switch off at -13inHg since it gets there pretty quick. I get two pumps of the brake, and it fires up and draws back down to -13 in about 15-20 seconds. |

Vacuum pump mount plate: 3.5 hours

(lots of measuring and a couple false starts on layout.)

pressure switch and bracket: 1 hour

tank and hose: 1 hour

-----

total: 5.5 hours